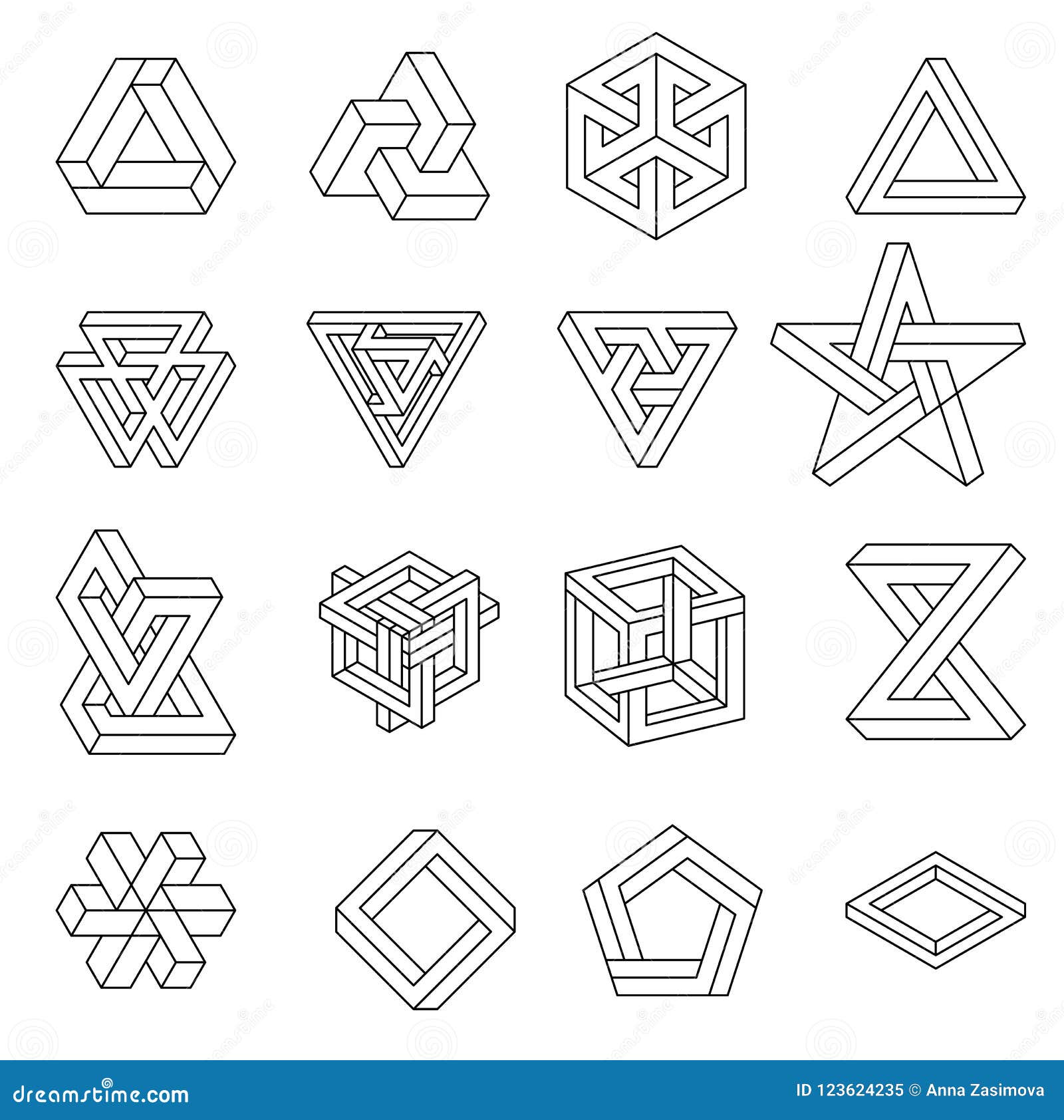

Note: The term "curve" in mathematics refers to a path that does not have be straight, although it can be. The shape is defined by top and bottom curves, which we will call a 1 and a 2 (Figure 3). You can follow the procedure for this project to make your own 3D illusion shapes even if you do not understand the math in this background section.įirst, you will create the outline of a two-dimensional shape in the x- y plane. Note: Depending on what math classes you have taken in school, you might not have seen all of the vocabulary used here, and that is OK. The process to generate the three-dimensional shape based on a desired two-dimensional shape is explained in detail in the paper, but we will summarize it here. In this project, you will choose your own 2D shape and make it into a 3D shape that produces an "anomalous mirror symmetry" illusion. Sugihara's paper include a boat, a car, and a fish. This illusion works for other shapes as well. Alternatively, you can put the object in front of a mirror and its reflection will appear flipped so the arrow points to the left. In other words, you can rotate the object 180° and it will still look like the original shape, an arrow pointing to the right. You can see in the side view in Figure 2, however, that the top and bottom surfaces are not flat at all - they follow a three-dimensional path. This illusion works because, from the correct viewing angle, your brain interprets the top of the object as flat. Top and side views of the "impossible arrow" reveal that it does not look like an arrow at all when viewed from these angles. Other collaborators include chemical giant BASF and TIGER Coatings.Figure 2.

Ricoh 3D is the latest industry partner to join forces with Impossible Objects to drive additive manufacturing forward. The CBAM process can create strong and resilient fine or flat parts, which is important for applications like drones these have been impossible with FDM and FFF technologies due to the short, chopped fiber formation and lamination between layers, which cause parts to fall apart under force. By combining high-performance polymers like Nylon and PEEK with carbon fiber and fiberglass sheets, parts printed with Impossible Objects machines are stronger, lighter, have better dimensional accuracy, and have better temperature performance than what’s possible with conventional 3D printing methods. Impossible Objects’ proprietary CBAM technology can produce parts up to ten times faster than conventional fused deposition modeling (FDM) 3D printing. By collaborating with the team at Ricoh 3D who recognizes the transformative potential of additive manufacturing, together we will bring these competitive advantages to more organizations across Europe.” “Fortune 100 companies, government agencies, and more have already put it to work to create everything from car and aircraft parts to athletic gear. “Our CBAM process represents a significant leap forward in 3D printing, with faster speeds, better material properties and wider material selection,” said Robert Swartz, chairman and founder of Impossible Objects. “Impossible Objects’ CBAM process is nothing short of a revolution in the way composites are manufactured, so we are proud to be working with the company to be at the forefront of the European movement.”Ĭomposites including Carbon Fiber PEEK and Carbon Fiber PA12 are available through Ricoh 3D’s AM service bureau immediately. These new materials will change the game across a number of industries,” said Mark Dickin, additive manufacturing & molding engineering manager at Ricoh 3D. “Composites are set to be an area of huge growth in additive manufacturing in the coming years. Composites boast key advantages for 3D-printed parts, including superior strength-to-weight ratios, fewer geometric restrictions, superior high-temperature performance, and greater chemical resistance. Impossible Objects’ composite-based additive manufacturing (CBAM) process enables the production of stronger parts at costs lower than any other 3D printing process. NORTHBROOK, Illinois – A new partnership between 3D printer and materials company Impossible Objects and leading 3D printing specialist Ricoh 3D will make strong and lightweight printed composite parts available to Ricoh 3D’s customers in Europe for the first time.

0 kommentar(er)

0 kommentar(er)